Products

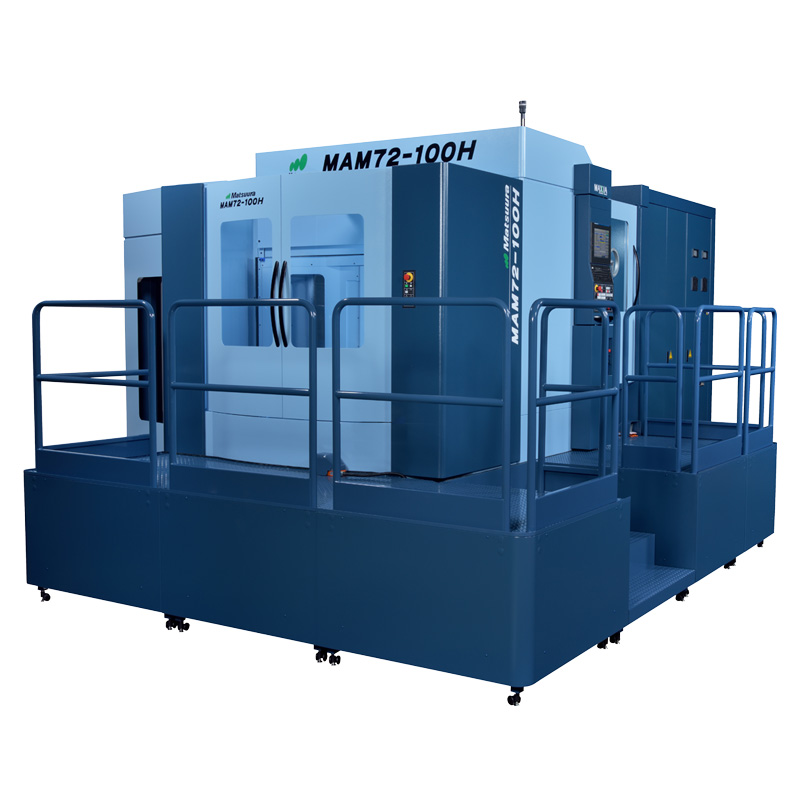

5-Axis Horizontal Machining Center MAM72-100H

5-Axis Horizontal Machining Center

MAM72-100H

Our Largest Capacity 5 Axis Machine Ever

Maximizing its production ratio by ATC & APC system.

The DD motor achieves high positioning & high-speed rotation

Matsuura’s unique MAXIA spindle that works for any processing

Safe and Secure IPS & MIMS

If you're not sure which product to choose...

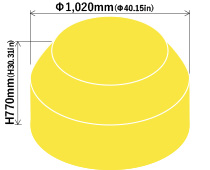

Max. Work Size

Max. Work Size *with conditions

- Max. work dimensions

- Φ1,020×H770mm

(Φ40.15×H30.31) - Loading Capacity

- 780kg(1,719lb.)

Features

Extensibility

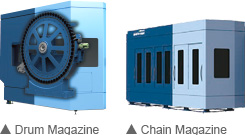

ATC Tool Magazines

- Standard

- Drum Magazine 60 tools

- Option

-

Chain Magazine 120 tools

Matrix Magazine

114/144/174/209 tools

120/150/180/210/245 tools

APC Pallet System

- Standard

- PC2

- Option

-

Floor Pallet System PC6

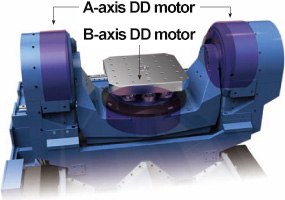

Ultra Robust DD Motor

Simultaneously achieves high-precision positioning and high-speed rotation.

This helps shorten machining times.

A-Axis : 50min-1

B-Axis : 75min-1

Sample Work

CONTACT

Please feel free to contact us.

We also accept suggestions for customizations and operations.