Products

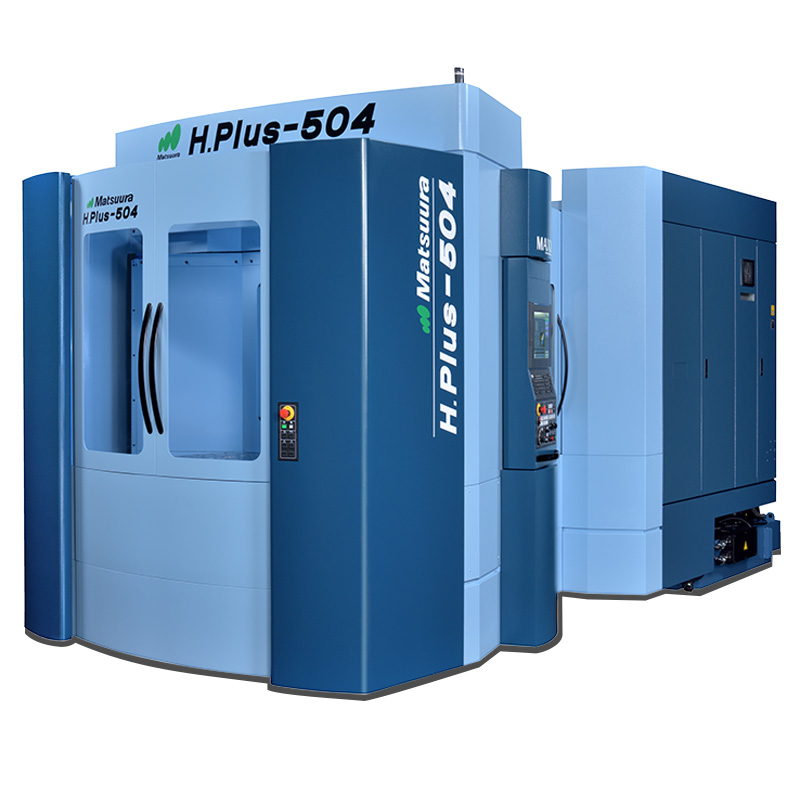

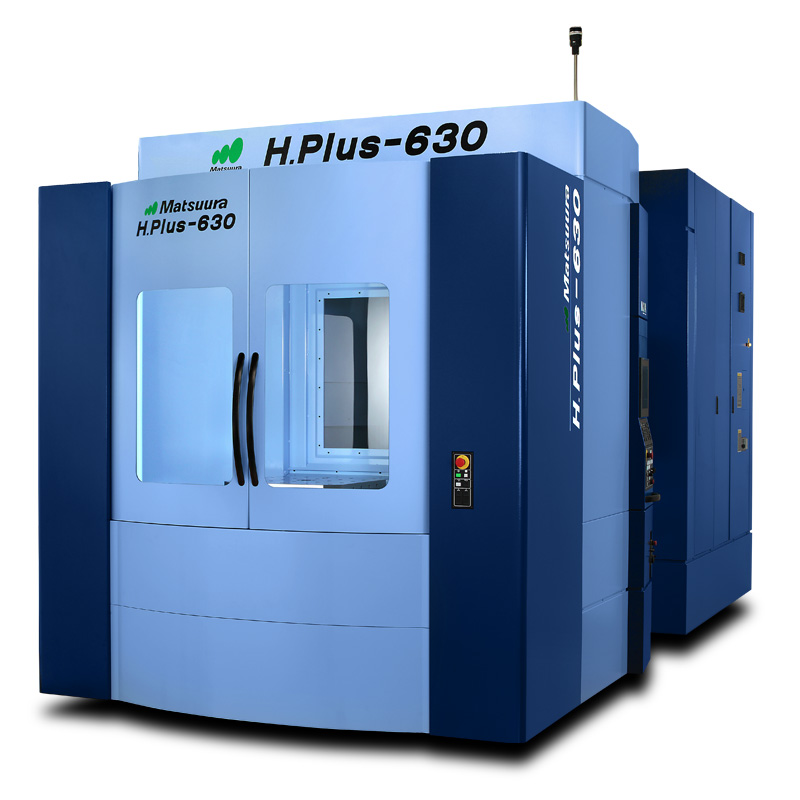

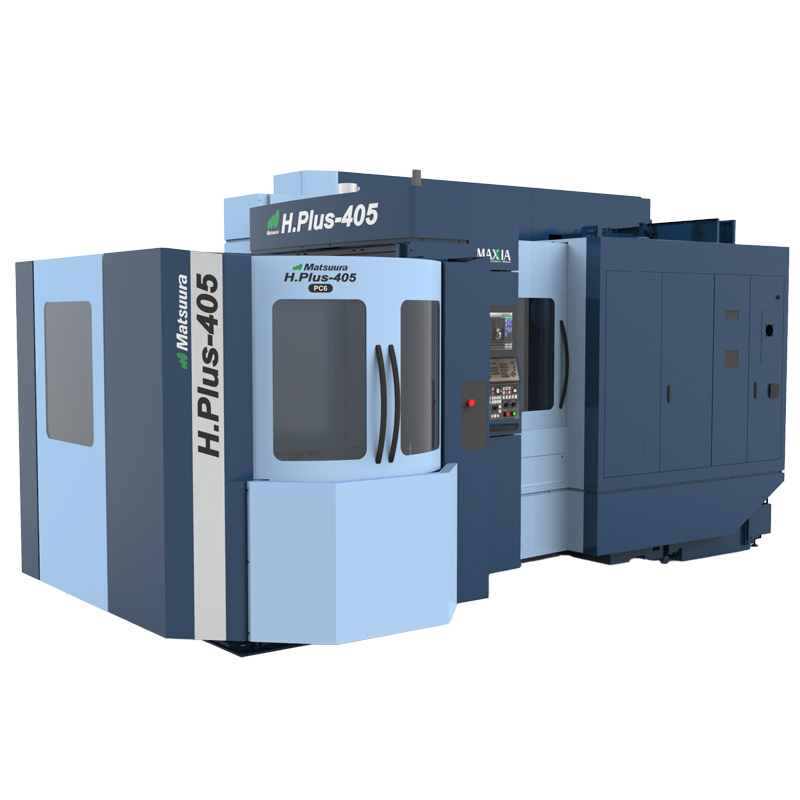

Horizontal Machining Center H.Plus Series

High Rigidity, High Speed, Compact

World-renowned All-rounder, H.Plus Series

Expandable ATC/APC options, strong support for long hour unmanned operation

and various production, meet a wide variety of needs.

LINE UP

OPTION

Automation and Unmanned System

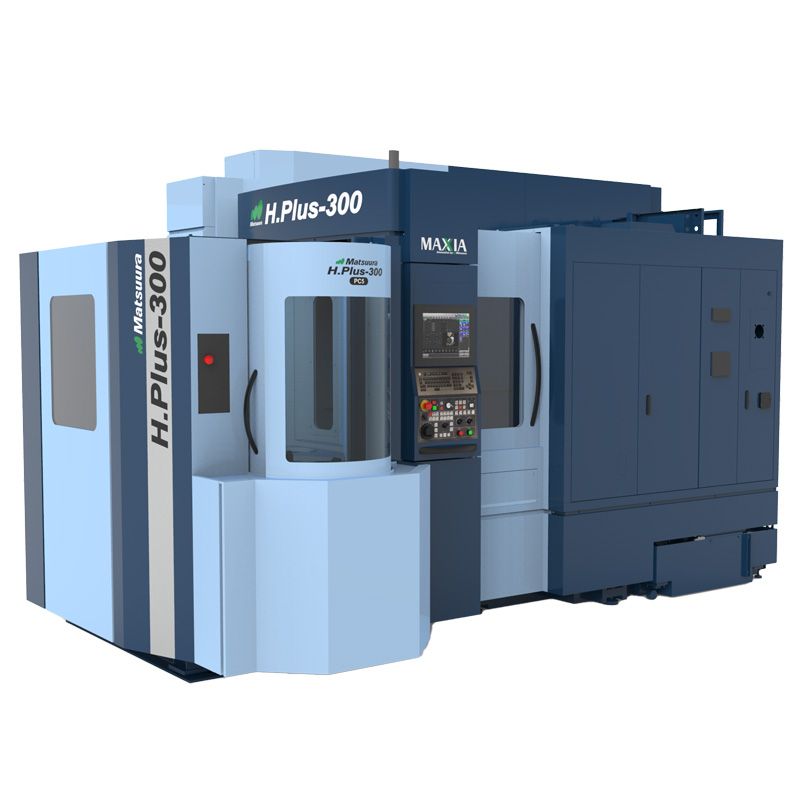

H.Plus-300 PC5

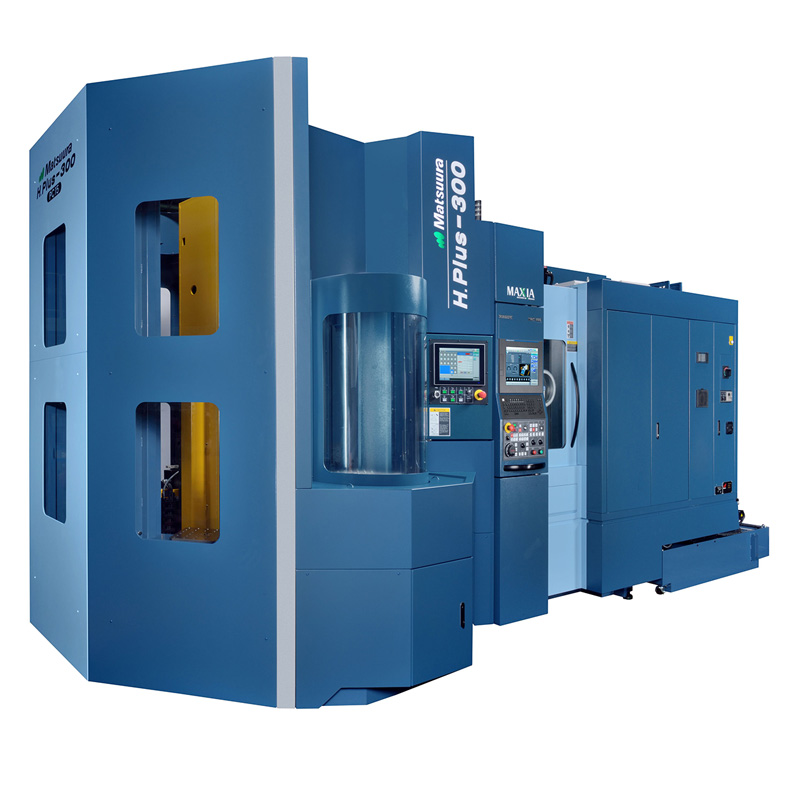

H.Plus-300 PC15

H.Plus-405 PC6

H.Plus-405 PC12

H.Plus-500 PC6

Learn more about automation and unmanned operation solutions

Features of the H.Plus Series

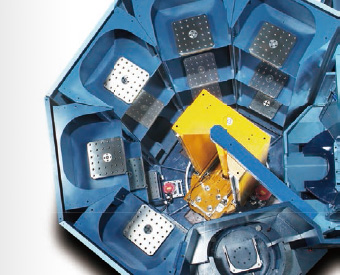

Broad Expansion Options

Powerful Support for Unmanned Operation & Flexible Manufacturing System

Broad lineup of ATC/APC expansion options. Selecting from them to meet your needs, it realizes unmanned operation & flexible manufacturing system.

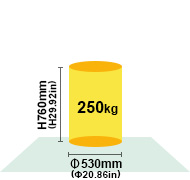

PC5

H.Plus-300

5-Pallet Changer(Floor Pallet System)

PC15

H.Plus-300

15-Pallet Changer(Tower Pallet System)

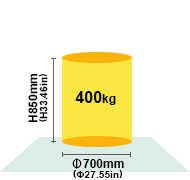

PC6

H.Plus-405

Floor Pallet System

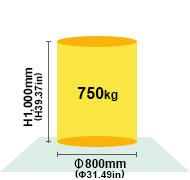

PC12

H.Plus-405

Tower Pallet System

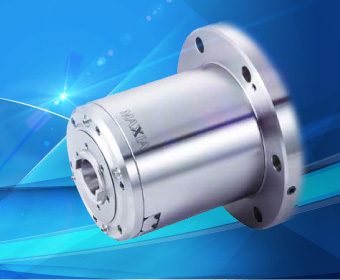

Spindle

Spindle

spindle from Mtsuura – the pioneers of High Speed Spindles.

spindle from Mtsuura – the pioneers of High Speed Spindles.

Renowned the world over for their reliability, precision, rigidity &

outstanding durability and performance,![]() is bland name

is bland name

for Matsuura spindles – the leading thechnology innovators for HSM spindles.

Equipped with a proven auto-grease lubrication system.(#40)

Pursuing ever more reliable and maintenance free technologies,

the proven auto-grease spindle lubrication system is a standard

feature on Maxia spindles – delivering maintenance free operation for life.

More Matsuura!

CONTACT

Please feel free to contact us.

We also accept suggestions for customizations and operations.