Looking Back on 30 years

High-Speed Machining

Looking Back on 30 years

Looking Back at Matsuura’s 30 Years Technological Innovation in the Heisei Era (1989-2019)

![]() History 02

History 02

High-Speed Machining

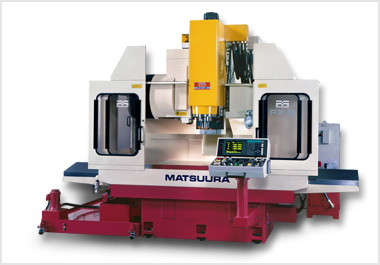

FX Series

High-Speed Machining

FX series

Pioneer of high speed machining,Adoption of high speed spindle.

Machining capability 3 times higher than conventional machines.

Following the 1985 Plaza Accord, Japan’s economy suffered from recession caused by a strong yen and trade friction with the U.S. that led to strict export regulations on machining centers.

The question: What kind of machine could break through these circumstances? The answer: One equipped with ultra-high-speed machining technology that could enable improvements to productivity. To this end, in 1989, the FX-5 was developed.

In collaboration with Yaskawa, Matsuura developed a high-speed spindle equipped with a dual winding spindle motor and high-speed/high-accuracy control functions.

This spindle was capable of reaching 20,000min-1 and had all-encompassing cutting capabilities, from heavy duty cutting at low speeds to aluminum machining at high speeds.

History of FX series

History of FX series

1989

FX-5

Equipped with 20,000min-1 (JIS

#40) spindle endmill machining.

MRR of 1,000 cc/min or more.

1990

FX-10

Equipped with 20,000 min-1(JIS #40) spindle.

Capable of machining large aircraft parts.

Feedrate 2,040/1,020/400mm.

1991

FXH-45

Equipped with 20,000min-1(JIS #40) spindle

1994

FX-1

Equipped with 30,000min-1(JIS #30) spindle

Precise small mold cutting

1995

FXH-90

Equipped with 20,000min-1 (JIS #40) spindle

1996

FXH-70

Equipped with 27,000min-1 (JIS #40) spindle

1997

FX-5GPC40

Equipped with 27,000min-1(JIS #40) Spindle

Rapid traverse 50m/min